EXPERTISE / PRINT TOOLS

Plates & Sleeves for Flexographic Printing

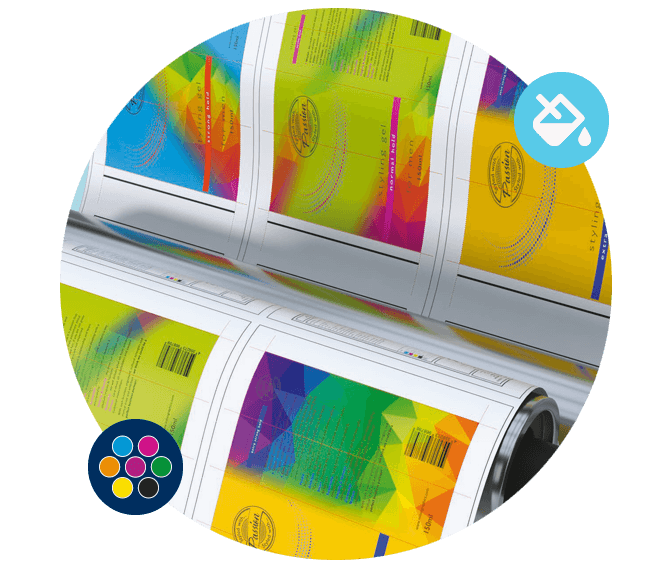

Excellent print results requires excellent printing tools. Our expertise in extended colour gamut printing, high-quality printing plates & sleeves are contributing highly to your great flexoprint results!

Plates & ITR Sleeves

Miller Graphics Group are one of Europe’s leading suppliers of flexo plates and sleeves. Our production sites have pioneered with HD developments which allow us to combine the very best in HD software with superior plate types and ITR sleeves.

Our extended colour gamut tool with fixed colour palettes and our advanced screening technologies on plates help our clients achieve outstanding printed results and generate considerable ink saving on top of that.

We listen to our customers and embrace all available and new plate and sleeve technologies to find the most effective solutions. Miller Graphics will always be at the forefront of innovation and development to the benefit of our clients.

Direct Engraved Elastomer Sleeves

High-quality elastomer applied on fiber glass carriers are directly engraved with high definition lasers.

Our sleeves fit straight onto the press mandrels so there is no need for bridging tools.

The HD direct engraving process with the finest resolution and advanced surface screening on our durable and hard wearing sleeves offers the best ink transfer on all substrates.

MG Shift

Connecting brands to a broader colour space by using the extended colour gamut.

MG Shift supports the printing process by reducing complexity and making the print process more efficient and consistent. It gives access to around 90% of the Pantone colour space using a set of predefined process colours. Benefits are obvious and several: no time consuming stops to change colours and cleaning. Thus making it better for the environment and allowing much faster job changeover.

his is an excellent way to help meeting the always shortening time to market and stringent deadlines.

Plate Mounting

Accurate pre-mounting of plates on Mylar for corrugated board printing on high-performance digital mounting equipment. Camera control offers the highest accuracy in register.

Quality control and risk management are secured by real time wet proofing on the mounting equipment.

The selected choice of plate, tape, foam and carrier, in combination with advanced colour management offers the best possible print results on corrugated board.

Frequently asked questions

What are flexo printing plates and how are they used in packaging?

Flexo printing plates are photopolymer plates used to transfer ink onto packaging materials. They are essential for high-speed, high-quality flexographic printing across various substrates.

Can flexo printing tools be customized for different packaging materials?

Yes. Flexo plates and sleeves can be tailored to suit various substrates including film, paper, and corrugated board, ensuring optimal ink transfer and visual impact.

What are elastomer sleeves used for in flexographic printing?

Elastomer sleeves are used in flexographic printing to deliver high-speed, high-precision results for packaging applications. They offer seamless print quality, reduced setup time, and can be reconditioned for sustainability.

How do flexographic sleeves compare to photopolymer plates?

Flexographic sleeves are ideal for long, repetitive jobs with high accuracy and minimal downtime. Photopolymer plates are more agile and cost-effective for short runs and frequent design changes.

What printing applications are best suited for flexographic sleeves?

Flexographic sleeves are ideal for flexible packaging, heat-shrink sleeves, hygiene paper, medical packaging, and specialty papers. Their durability and precision make them suitable for high-volume production.